Menu

-

- Home

-

Paddle Sports

-

Resin and Fibreglass

-

Marine

-

Transport

-

Specials

- blog

-

- 587-855-1304

- Login

-

CAD

Danielle's Red Canoe Refinish with Interlux Marine Paint

February 24, 2024 3 min read

We are happy to share this refinish and repair that Danielle has completed on her 1977 fiberglass canoe that she and her family used and continues to use today. The canoe had been worn down and the red gel coat had oxidized and lost its colour, so the canoe needed to be refinished. The hull is in good order without holes or impact damage, so the work that she did was cosmetic and painting. The canoe had to have the gunwales removed so that the whole interior and exterior surface could be prepared, sanded and decontaminated before new paint can be applied. The old gel coat has to be aggressively scuff sanded and faired so that the paint will have a good surface to bond to as well as present a smooth finish.

The techniques and tools that Danielle used are simple and inexpensive, however, her project is a good example of applying the paint well with proper techniques to get a high degree of finish. The technique used to apply the primer and paint is called rolling and tipping. The paint is applied with a high-density foam roller in small 2 square foot areas and then immediately tipped with a foam brush to knock down any textures or bubbles from the roller. The key to success when applying top coats to fiberglass surfaces is to apply many thin layers instead of thicker layers. Fiberglass, unlike drywall or plywood, is a completely sealed surface so any material applied to the surface will sag or slouch if there it too much volume. By rolling the surface we apply a super thin and even coat of colour with a second coat making the surface super smooth and semi-gloss. The tools required are a paint tray, roller handle, foam roller, foam brush and personal protection gear (gloves and organics cartridge mask.) The roll and tip method can be done by any builder no matter what experience they have a good result; Danielle has perfected this technique for her canoe.

Once the surface is sanded, the outside and inside of the hull is coated with Interlux Prekote primer so that the new polyurethane marine paint will bond well to the old gel coat surface. Interlux does recommend priming the surface before applying polyurethane to gel coat, polyester (fiberglass resin) or epoxy surfaces. Prekote primer is rolled and tipped onto the surface, where thin coats are applied with a high-density foam roller and the air bubbles are knocked flat with a foam brush. The primer is left to dry and is sanded between coats with 220-600 grit sand paper depending on any surface textures. A second coat of primer is applied to the surface, and it is also sanded for the first coat of Topside Marine paint. Prekote primer has an additive in the paint that makes it easy to sand and fair so that the first paint layer is very smooth. This surface can be faired and sanded with an orbital sander or block sander in preparation for Polyurethane Marine Paint.

Danielle has applied the Interlux Brightside Red paint extremely well by using the foam rollers and foam brushes for the semi-gloss finish. The paint will duplicate the surface beneath it, so if there is pitting or dust debris in the primer layer the paint will not body fill the holes. Danielle has taken the time to sand the surface so that the paint can lay flat and even which makes the paint look ideal. Two thin coats have been applied to have a rich and opaque colour, as well as, be durable if the canoe hits rocks or is pulled on shore.

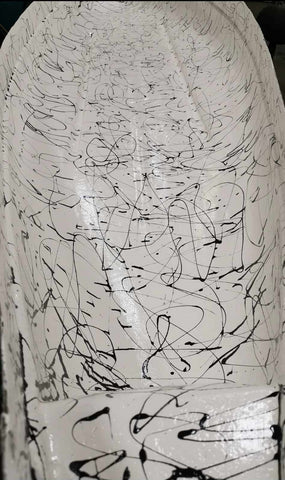

The inside of the canoe has been primed and painted, but Danielle has added the dripped paint look that the original canoes had where the paint is spread on the inside to create a visual effect. Danielle used syringes and black polyurethane paint to create these marks. This is an attention to detail that we commend where the builder has refinished the canoe but maintained its original character and design.

Danielle has also added a painted name on the bow of the canoe, where white letters have been painted onto the red hull. This takes considerable attention and care to have such a degree of finish. Having the name painted onto the hull will be more durable than vinyl decals, but it takes some serious skill to accomplish to this level.

Once the detail work is completed, Danielle has reinstalled the gunwales, seats, yoke and handles to compete her restoration.

Products used:

- Interlux Prekote Grey

- Interlux Brightside Red

- Acetone

- Foam Rollers

- Roller Handle

- Foam Brush

- Acetone

- Sandpaper

Leave a comment

Comments will be approved before showing up.